Les (Jim) Fischer

BigJimFish

Written: Nov 12, 2020

Shooting the Vudoo V-22 off of a wire spool.

Table of Contents:

- Introduction

- Vudoo V-22 Core Technologies

- Other Unique Features

- Fit, Finish, and Physical Description

- How They Shoot

- Ammo Choice Discussion

- Feeding and Ejection Reliability

- Summary and Conclusion

Introduction:

I think I first heard of Mike Bush somewhere around 2012. At that time he was modifying single shot discontinued Remington 40x rifles into repeaters that fed from a 3-D printed magazine he was making. His work had a good reputation. At that time I did not realize this was prototyping for him with the goal of re-introducing an updated 40x that would be a repeater instead of single shot based on his designs through Remington. I was not really interested in expensive modifications to an already expensive used 40x, and so, not having not found the true to scale .22lr of my dreams, I was separately trying to convince a few action makers to produce .22lr 700 platform custom actions using an AICS compatible adapter block I sketched out for them with a sleeve adjustable in two dimensions housing a Marlin 880 magazine instead of the AICS sized standalone .22lr magazine concept Mike was working on. I frankly never thought that an AICS .22lr magazine could be made reliable without any end user adjustability. I thought the variance from chassis to chassis to bottom metal on dimensions was just too great. Nobody that I harassed had any interest in working on 700 footprint .22lr receivers (pretty funny now isn't it), so, when I eventually acquired a suitable full scale .22lr, I ceased to think much on the idea.

A Remington 40x converted to repeater which uses Vudoo magazines

Focus was changing for Mike as well. Remington did not end up deciding to do the project with him. Instead, they went for general self-immolation on unrelated grounds. Mike ended up joining with Paul and Jill Parrot to form Vudoo Gun Works to produce a much higher grade of the concept than he originally anticipated. I sort of watched this from afar until last year when I wanted to do some harmonics testing on a Proof carbon fiber barrel in .22lr. I needed a solid platform, solid smith, and access to steel barreled versions of the same platform cut by the same smith. I was investigating this path when the Lapua test center opened up in Ohio and made things even easier since it regularly tested steel barreled Vudoos. Given the good things I had heard, I was pretty excited at the confluence of factors. I asked Mike if he was interested in this investigation and he came onboard. As long as I was using a Vudoo and collecting data from a bunch of Vudoos, I figured a review was also in order. After all, what other review is going to have data from seven different Vudoos shot under near ideal test conditions.

Vudoo V-22 Core Technologies

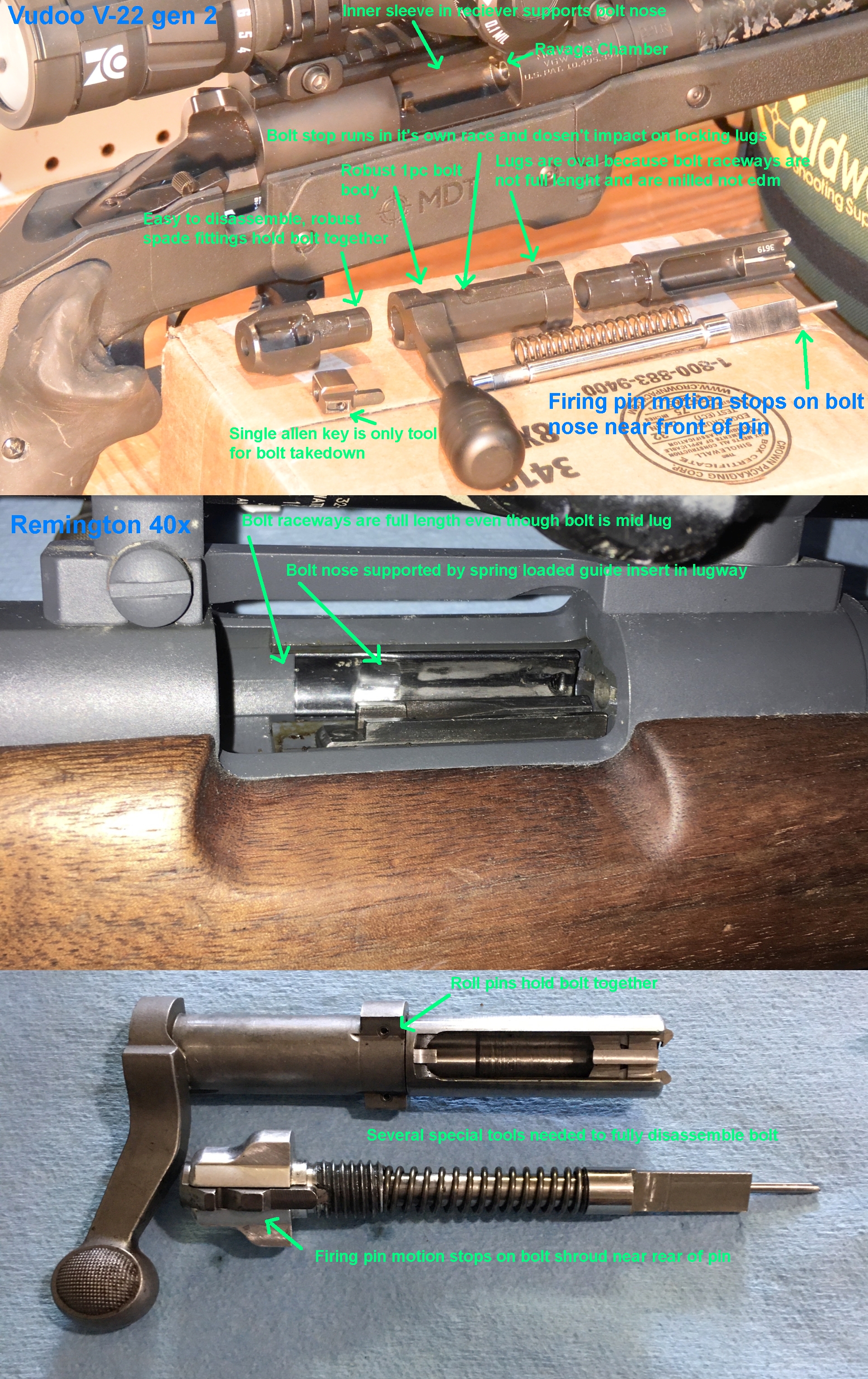

We should start this off by saying the V-22 is NOT a 40x repeater conversion. Both the 40x and the V-22 have a Remington 700 footprint and accept 700 triggers, but that is about it for similarities. The first thing is to understand that the 40x is essentially a Remington custom shop modification to a 700 short action. They started life being pulled from the 700 production line partway though. This results in some compromises as far as

fitness for the .22lr cartridge is concerned. Most notably, the lug raceways extend the full length of the receiver even though it is a mid lug action. This results in the front, non-rotating, part of the bolt not being supported by the action body, but rather by a strange spring-loaded alignment guide fitted into the left lug raceway. This results in some play in where the bolt nose can actually end up and, therefore, some variance in where the firing pin strikes the case head. The V-22 has lug raceways that only extend to the lugs. In front of that, the receiver is narrower and supports the forward non-rotating bolt section with its body. Vudoo holds U.S. Patent # 10,495,394 relating to this. The patent is essentially for the idea of press-fitting and welding a cylinder inside of the front of the action, resulting in the smaller diameter forward section. In addition to supporting the nose of the bolt, this construction method furthermore lowers the cost of production, as Vudoo can mill the shorter resulting lug raceways in the rear of the receiver instead of EDM or broaching full length raceways. This is why Vudoo's lugs are rounded instead of rectangular. It probably also contributes to why Vudoo bolts feel so smooth. EDM does not actually produce that smooth of a surface. It is essentially electrical erosion and is not as smooth as cutting with a bladed tool.

In the same vein as supporting the bolt nose with the action body, Vudoo also better supports and guides the firing pin. The firing pin on a 40x comes to a stop on the cocking piece near the back of the firing pin. This is a long way from where it's impacting the case - at the front. The V-22 firing pin is stopped on the inside of the front of the bolt, near the front of the case. This difference is also why the V-22 is entirely dry-fire safe though you will probably still cringe to do so from the years of training not to dry-fire .22lr's.

Image illustrating the key engineering differences between a Vudoo V-22 and a Remington 40x action.

As Vudoo has updated its design over the short duration of its manufacture, Vudoo has further distanced its firing control system from the 40x. Originally, the cocking piece was a simple Remington 700 piece, like the 40x, and the bolt disassembled using the same special tools. On current production (gen 2) V-22s, Vudoo uses its own cocking piece, which is threaded instead of pinned to the firing pin. This allows tighter tolerances and also allows for the entire bolt, even down to the firing pin spring, to be disassembled with only an Allen key, though I would suggest using a wood-jawed vice while doing so as that will make it much easier. The V-22's firing pin has a unique half moon shape to its tip which follows the contour of the rim. It is the single largest area firing pin tip I have ever seen, engaging at least twice the area of any other .22lr firing pin and making it pretty unlikely that you will suffer an ignition failure from striking an area of the rim with a priming compound gap. The standard firing pin spring is 18lbs and is optimized for soft Lapua brass. When I used the standard spring on harder Eley and CCI cases, I still had ignition 100% of the time, but I did notice the indentation in the case rims from the firing pin was pretty light. A 22lb firing pin spring is available for those harder cases and, given the easy takedown of the bolt, is pretty easy for the user to install.

Perhaps Vudoo's most obvious piece of new technology on the V-22 is the AICS footprint .22lr magazine. It is not so much that the idea of a big form factor magazine necking down and holding .22lr cartridges is new (Ciener pattern .22lr magazines that fit unaltered AR-15 lowers are pretty common), it is more that Vudoo produced an AICS form factor .22lr magazine which, in concert with their bolt, manages controlled round feed and works well in most examples of most chassis. The Ciener, and most other .22lr systems have a feed ramp. This is not ideal with soft lead .22lr bullets. It is really essential for best accuracy to go from the magazine into the chamber without scraping on a hard steel feed ramp. Accomplishing this was the primary goal of the years of trials with 40x conversions that Mike did.

Next on the list of Vudoo's major technologies is the ravage chamber. As we will discuss later, the V-22 is best consumed in barreled form so you will most likely be buying one with the ravage chamber, though they can spin one up for you with one of the other popular match .22lr chambers such as the EPS if you are an Eley fan. The ravage chamber is based on the Winchester 52d chamber but is altered some to best fit the Lapua bullet and to be able to extract that round unfired as well. The 52d is probably the tightest of all match chambers. The ravage is closer to average for match chambers. It will extract unfired Lapua and most, but not everything, else. CCI in particular may chamber hard and fail to extract. Having tested a good variety of .22lr in the ravage chambers of several Vudoos I have found it to shoot a variety of ammo well.

Other Unique Features

In addition to the major technologies mentioned, Vudoo also incorporates a few smaller unusual changes. The first of these is an easy-to-remove ejector. The ejectors on .22lr often protrude into the line of the bore and therefore can damage your cleaning rod or require you to use a .17 caliber one. Vudoo has made their ejector very easily removable with a single screw accessible though the mag well with the stock attached. I suggest you remove it for each cleaning.

I recommend removing the ejector for cleaning. It doesn't look like it extends into the bore line, but it does and if this had been a coated rod instead of brass, that would be it for the rod.

Along the theme of cleaning. Vudoo has designed a unique hybrid cone breach on the barrel which has a good bit of bulk around the chamber but also features relief towards the edge of the breach face so that crud has a place to go and not interfere with the bolt closing in the event you are running a silencer or just going a long time between cleanings. The first generation of this hybrid breach was almost to a cone breach but the later is almost to a traditional flat breach. You can order with either of these or a traditional breach like I did if you don't tend to run dirty.

The three types of breech that a Vudoo can be purchased with

Virtually all match grade .22lr rifle barrels are 1-16 twist and button rifled, often with odd rifling profiles and taper lapping. These were the things that the consensus in the community deemed desirable and most effective. Mike was not convinced and, after a good deal of testing, disagreed. The barrels he uses for Vudoo's house Ace barrels are cut rifled as are all the others (Bartlein, Krieger, and Proof) that Vudoo commonly stocks and installs if customers so desire. For those not aware, cut rifled barrels are more, not less expensive to manufacture. Mike first started to consider barrel twist rate in the .22lr when he found that the BC he was seeing in the real world from .22lr at range was not as good as expected. He thought that perhaps the .22lr is not totally stable as it gets further down range and its rate of rotation decays. It is common in short range benchrest disciplines to run twist rates on the ragged edge of stable as the less the overspin, the better accuracy will be, so long as you don't cross into unstable territory. Mike figured this might be what was happening and tried some other twists. Most were terrible failures but he eventually got 1-9 working and he found them to have an advantage in both accuracy and drop as distance increased. Vudoos can now be ordered with 1-9 twists as well as 1-16.

Over the course of the astounding 4k+ V-22 actions that Vudoo has made in just these last four years, they have gone through three slightly different versions of their repeater action, produced a V-22m long variant for 17hmr and .22mag, and also produced a V-22s single shot variant. They have chosen to name the generations of these actions in a truly confusing way. They have a gen 1, 1.2, 2, and 3. The 1, 1.2, and 2 all represent different bolt designs for the repeater actions. The gen 3 is only found in the single shot V-22's benchrest action. The action I have on my review rifle is a gen 2 V-22 and that is the only variant I will be talking about because if you buy a rifle today that is what you will get. If you are interested in the differences between the variants and how each disassembles, Vudoo has produced a video detailing the disassembly procedure of each generation of action which amply illustrates the differences between them.

Fit, Finish, and Physical Description

V-22 actions cost a custom price and they are machined to that level. The V-22 is one of the smoothest custom actions I have ever run - and I have run more than a few. Being a .22lr action, the V-22 has a good deal more complexity than centerfire actions. Each part of the bolt as well as the shroud are held together with spade fittings. The fitment of these pieces is excellent as is the fit and machining on the firing pin which runs though all of them. The machining on the crown and in the chamber also appeared excellent. The chamber has a fine mirror finish and the machining on the crown is quite clean and with no markings on the inside of the bore. The crown appears to be both recessed and 11 degree. Sort of a combination of the common recessed crown seen on most centerfire guns and the Anschutz 11 degree crown. As with the part fitment and machining, the finish is also of good quality and excellent craftsmanship. The action comes Melonited standard, though you can also choose to have it Cerakoted. The barrel is Cerakoted standard. Vudoo barrels come standard threaded with the 1/2 x 28 TPI pattern common to rimfires and include a thread protector finished to match the barrel.

Vudoo V-22 barreled action unboxing

As previously mentioned, the action of the V-22 is constructed in two pieces with an inner sleeve to support the bolt nose extending as far back as the lugs being press fit into the full length outer receiver. The fit is quite good and I had not noticed the joint between the two until I specifically looked for it, as it passes for a fine machining mark. The V-22 action is of the lathe-turned variety and, as such, the rail is a separate piece of metal. It can be purchased in 0-60moa inclinations with 30moa being standard.

The recoil lug on the V-22 is integral and I think is a bit unfortunate in dimensions. Being a .22lr and therefore having little recoil, the lug protrudes into the stock much shallower than a centerfire lug. For some reason, however, it is actually far thicker than the average centerfire 700 pattern lug. I think this is an unfortunate choice because it would have been quite possible to make the lug slightly smaller than most centerfire recoil lugs in all dimensions save the location of the rear of the lug. In this case, the Vudoo action would have been able to drop into stocks bedded for centerfire rifles with likely good results. Lathe-turned actions might not be as trendy as those with integral rails, but their external dimensions are straighter and rounder, and this would have allowed people to run their Vudoo in an action bedded for their centerfire with no fuss and, I suspect, good results. When I first saw an image of the receiver with its small lug, I thought this was the plan. Sadly, no. The recoil lug dimensions and the use of standard trigger pins instead of a hanger or shouldered threaded pins are the only improvements that have come to mind in the process of doing this review.

Also integral in the V-22 is bolt handle. This is uncommon in most centerfire actions. Usually the bolt handle is welded to the bolt body. The integral handle is a stronger solution. The bolt knob is threaded as per usual with three standard offerings. The medium knob is present on the rifle constructed for me.

How They Shoot

It is unusual when doing a review to have a substantial amount of data from a variety of examples of a product, many of which were purchased on the open market and all of which were tested under near ideal and near identical situations. I have certainly never been able to provide that sort of depth, quality, and quantity of data before, but today is all our lucky day. I have data from seven different Vudoo rifles, all but two of which were purchased on the open market. I am fairly certain that all of the Vudoos except mine had ACE barrels with most being the Kukri profile, though I think there was an MTU or two. Of course, mine was the Proof carbon barrel used for the Proof barrel review that started this project. All of the rifles tested were chambered and barreled by Vudoo with their ravage chamber. The rifles were tested under indoor conditions at the Lapua test center with a variety of Center-X and a few Midas+ lots for the purposes of lot selection. Because the purpose of testing for most of the rifles was ammunition lot selection for purchase, a sub-optimal factor in the data is that there is variability in how many shots of each lot of ammo were fired, precisely what data was recorded for each, and how much of that data made it to me. The rifles were also not all tested at the same time and so the lot of ammo used varies. This presents both advantages and disadvantages in that lots of different ammo was tested, but not across the same set of rifles. In the end, I think the compiled data provides a pretty good idea of what sort of performance to expect from Vudoo's products, even if it doesn't answer all of my questions.

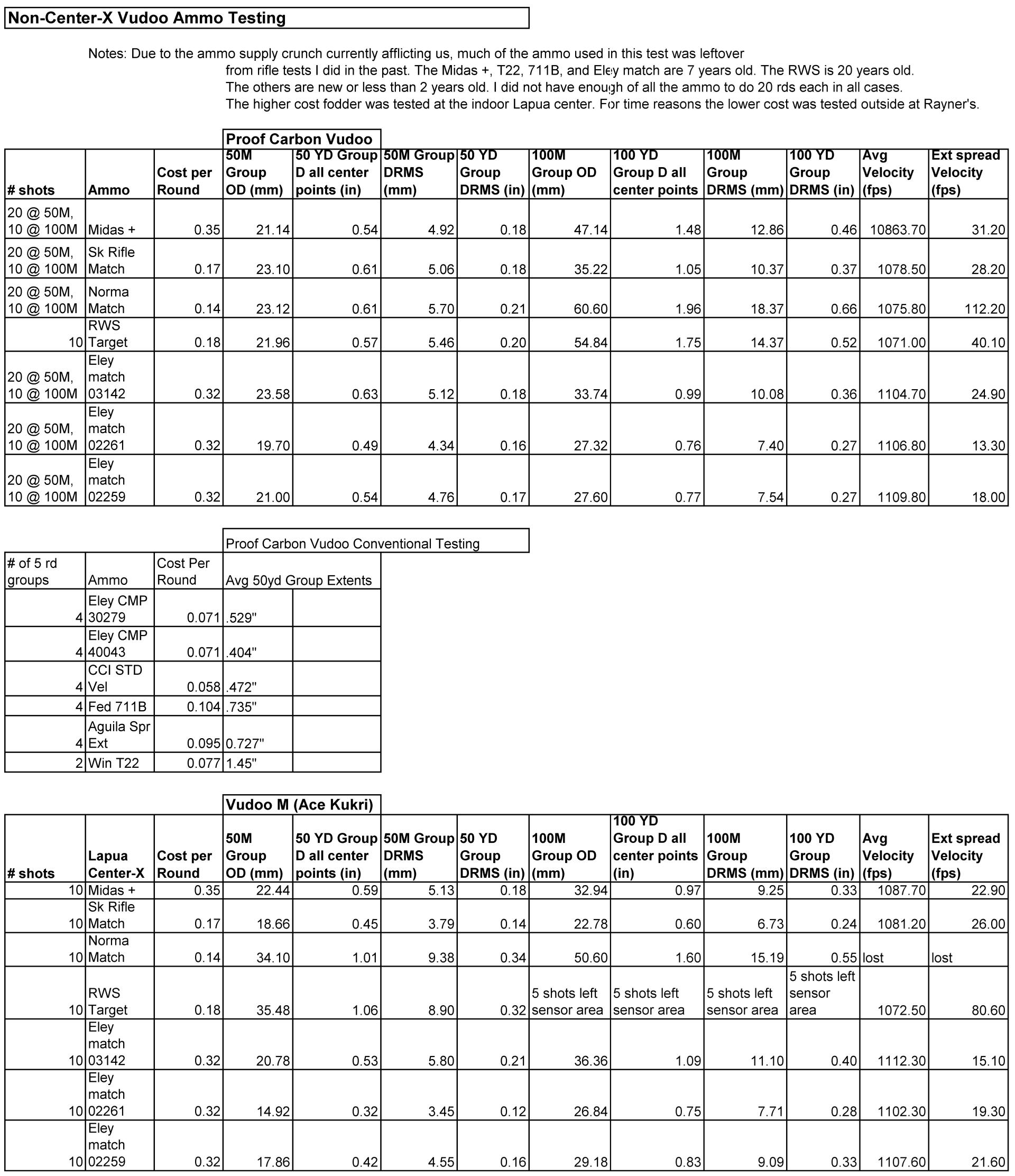

50M Center-X Lot Selection Test Summary from the Proof Barreled V-22