Haven't I read that a dirty chamber can lead to cold bore shot problems?

-

Whether you're a greenhorn or a seasoned veteran, your collection's next piece is at Bass Pro Shops. Shop Now.

bucko

1,353 posts

·

Joined 2014

Yes. The theory is, fouling builds around the case mouth, and the first shot from a cold bore is thus affected. The heat of that shot softens the fouling so it does not affect the next few shots the same way. I'm not sure about all that, but I know that the chamber leade will foul well before the bore, so I scrub the chamber much more often (in fact, I rarely clean the bore).

59 posts

·

Joined 2013

Is there such a thing as a 22LR chamber brush, I don't recall seeing them. Also is there a special technique for 22 chamber cleaning??? Thanks

10,084 posts

·

Joined 2010

Buy this Gunsmither tool or build your own.

![Image]()

Works great. i do not clean my barrels often, but always clean the chamber and bolt face after a shoot.

Works great. i do not clean my barrels often, but always clean the chamber and bolt face after a shoot.

4,455 posts

·

Joined 2015

Cleaning the chamber is described in this post.

The brush on the left is a Gunsmither. The one on the right is home made, with a .243 brush. I like the .243 brush better.

http://www.rimfirecentral.com/forums/showpost.php?p=7540465&postcount=15

The brush on the left is a Gunsmither. The one on the right is home made, with a .243 brush. I like the .243 brush better.

http://www.rimfirecentral.com/forums/showpost.php?p=7540465&postcount=15

65 posts

·

Joined 2016

I have (successfully) cleaned the chamber on a .22 using a bronze brush and some Kroil. I put the Kroil on a rag and left it in the chamber overnight and then put the bronze brush in a drill and (carefully) used it to clean the chamber. If you do this, you will break free a lot of accumulated lead and fouling.

I used this technique on a .22 that was jamming and it works quite well after the cleaning. I wouldn't do this as a matter of routine, but, if you have accumulated residue in the chamber, this will remove it.

I used this technique on a .22 that was jamming and it works quite well after the cleaning. I wouldn't do this as a matter of routine, but, if you have accumulated residue in the chamber, this will remove it.

15,631 posts

·

Joined 2004

There's a sticky in the Shooting Accessories forum on how to make cleaning tools, or you can buy the Gunsmither Brush n Mop...

Sticky Gunner Tools:

http://www.rimfirecentral.com/forums/showthread.php?t=504746

Gunner Tools

The Gunner Patchsnake is a typical button style puller. What makes it special is the strength and size of the button. They are intentionally made oversized, so the user can sand the button down to fit each bore precisely, giving as loose or tight a fit as you like. I recommend making two for most work. A looser button to swab out the majority of the crud with low friction, then I tighter button that will pull through with an audible squawk. The result is that the cotton patch is wedged into the rifling lands and grooves and cleans a barrel more thoroughly than one would expect. I've cleaned with every conceivable method and checked my results with a borescope. While nothing can equal a rod and brush, these tools come darn close and suffice for multiple cleanings between deep scrubbing with a brush- all in a nice small package that fits in any range bag.

![Image]()

![Image]()

![Image]()

![Image]()

The Gunner Jagsnake- this allows you to apply powder solvent and/or copper solvent, swab out the bulk of the solvent/powder residue and oil/lube to the bore with minimal friction.

![Image]()

![Image]()

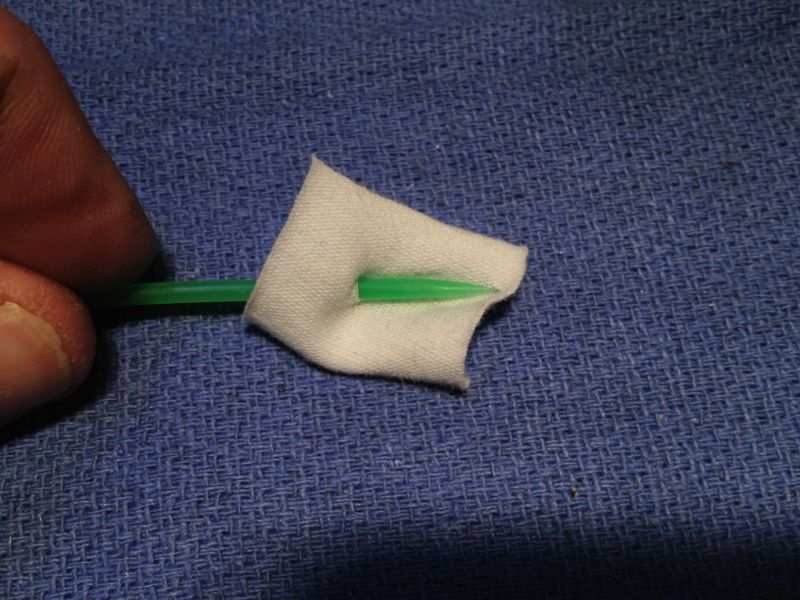

The Gunner Chamber Brush-

This allows you to clean the chamber and reach the depth of the dreaded "carbon ring" and leade with precise, controlled strokes without getting into the rifling. The finger loop gives control that simply is not possible with straight handles, and allows the user to clean most chambers at the range without disassembling the rifle. The Jagsnake and Patchsnake take care of the rest.

![Image]()

![Image]()

![Image]()

![Image]()

Sticky Gunner Tools:

http://www.rimfirecentral.com/forums/showthread.php?t=504746

Gunner Tools

The Gunner Patchsnake is a typical button style puller. What makes it special is the strength and size of the button. They are intentionally made oversized, so the user can sand the button down to fit each bore precisely, giving as loose or tight a fit as you like. I recommend making two for most work. A looser button to swab out the majority of the crud with low friction, then I tighter button that will pull through with an audible squawk. The result is that the cotton patch is wedged into the rifling lands and grooves and cleans a barrel more thoroughly than one would expect. I've cleaned with every conceivable method and checked my results with a borescope. While nothing can equal a rod and brush, these tools come darn close and suffice for multiple cleanings between deep scrubbing with a brush- all in a nice small package that fits in any range bag.

The Gunner Jagsnake- this allows you to apply powder solvent and/or copper solvent, swab out the bulk of the solvent/powder residue and oil/lube to the bore with minimal friction.

The Gunner Chamber Brush-

This allows you to clean the chamber and reach the depth of the dreaded "carbon ring" and leade with precise, controlled strokes without getting into the rifling. The finger loop gives control that simply is not possible with straight handles, and allows the user to clean most chambers at the range without disassembling the rifle. The Jagsnake and Patchsnake take care of the rest.

729 posts

·

Joined 2004

i use a NYLON bore brush with a slow speed drill motor and Hoppes 9 to thoroughly clean the chamber with using an in-and-out movement...

15,631 posts

·

Joined 2004

I've done that when I needed to remove a tough baked on carbon ring...but I try to avoid it. I prefer Otis 321 all bronze brushes- they're the perfect length to clean the chamber without getting into the leade. The 321's are very reasonably priced in 10-packs for $10-12, and come with handy individual plastic cases that I drill out to allow them to be snapped on the tool for storage.

OTIS 321 PISTOL BRUSH

Truth is, nylon vs brass doesn't make that much of a difference when it comes to the unwanted abrasive action of cleaning- abrasion comes from the silicates that are still used in rimfire primer compounds. I've found bronze brushes with bronze core wire work best to safely remove the carbon ring more effectively than nylon- for me.

My solution is to try to avoid letting them get that bad.

I designed my tools to allow for full cleaning of the 10-22 without disassembly. I don't strip them down after every range trip- I have 4 customs and my kids each have one so we sometimes mix it up and shoot 3-4 guns in one outing, but each only sees perhaps 2-300 rounds, so I give them a quick clean with Eezox and my cleaning tools. I strip them down for a thorough cleaning every 1500-2K rounds. I keep a small notebook in my range bag to keep track of each one and it's round count so I know when they're due for a full disassembly and scrub down.

DrGunner

OTIS 321 PISTOL BRUSH

Truth is, nylon vs brass doesn't make that much of a difference when it comes to the unwanted abrasive action of cleaning- abrasion comes from the silicates that are still used in rimfire primer compounds. I've found bronze brushes with bronze core wire work best to safely remove the carbon ring more effectively than nylon- for me.

My solution is to try to avoid letting them get that bad.

I designed my tools to allow for full cleaning of the 10-22 without disassembly. I don't strip them down after every range trip- I have 4 customs and my kids each have one so we sometimes mix it up and shoot 3-4 guns in one outing, but each only sees perhaps 2-300 rounds, so I give them a quick clean with Eezox and my cleaning tools. I strip them down for a thorough cleaning every 1500-2K rounds. I keep a small notebook in my range bag to keep track of each one and it's round count so I know when they're due for a full disassembly and scrub down.

DrGunner

4,009 posts

·

Joined 2013

I just take the bolt out & use a 223 chamber brush which works fine.

304 posts

·

Joined 2006

I feel-like a cheap-skate for using..

a folded back[i[e cleaner with Hoppe's! Didn't know I had tp spend more$$$!

Works great on revolver cylinders.

a folded back[i[e cleaner with Hoppe's! Didn't know I had tp spend more$$$!

Works great on revolver cylinders.

967 posts

·

Joined 2002

Clean the brush after use with Hoppe's!

When using a bronze bristle chamber brush, or bore brush, with Hoppe's, or any other ammoniated bore cleaner, be sure and flush the bronze brush with some brake cleaner type solvent to remove the Hoppe's residue.

Otherwise, your bronze brush will turn a nasty green color, and be severely weakend, and fall apart, giving much shorter brush life. I also recommend flushing out the bore mop also with brake cleaner. Do it outdoors, as that stuff is not too healthy!

Happy "10/22-ing" ya'll! Joe

When using a bronze bristle chamber brush, or bore brush, with Hoppe's, or any other ammoniated bore cleaner, be sure and flush the bronze brush with some brake cleaner type solvent to remove the Hoppe's residue.

Otherwise, your bronze brush will turn a nasty green color, and be severely weakend, and fall apart, giving much shorter brush life. I also recommend flushing out the bore mop also with brake cleaner. Do it outdoors, as that stuff is not too healthy!

Happy "10/22-ing" ya'll! Joe

604 posts

·

Joined 2006

Drilling the receiver?

Reading the various posts, it doesn't look like anybody here has drilled, or had a gunsmith drill, the receiver so the barrel can be cleaned from the correct end without separating it from the receiver. For a variety of reasons, I've never owned a 10/22. Nothing against them; just a not-unlimited budget and there was always something else I wanted more. I know lots of people who do have them. I suppose that's the same as saying I know lots of people. Has anybody here had negative experiences with doing that? It looks like some of the aftermarket receivers have this pre-drilled and some don't. Brownell's sells a jig for $50, which is probably about what your local gunsmith would want to do the job for you. Just curious.

Reading the various posts, it doesn't look like anybody here has drilled, or had a gunsmith drill, the receiver so the barrel can be cleaned from the correct end without separating it from the receiver. For a variety of reasons, I've never owned a 10/22. Nothing against them; just a not-unlimited budget and there was always something else I wanted more. I know lots of people who do have them. I suppose that's the same as saying I know lots of people. Has anybody here had negative experiences with doing that? It looks like some of the aftermarket receivers have this pre-drilled and some don't. Brownell's sells a jig for $50, which is probably about what your local gunsmith would want to do the job for you. Just curious.

1,805 posts

·

Joined 2015

I'm not sure how you drew that conclusion. I'd say many if not the majority of RFC members have a cleaning hole in the back of their receivers. The Brownells jig has been making the rounds on the Pay It Forward thread about 5 years, although many folks, like myself, just do the measurements, center punch, then drill free hand.Reading the various posts, it doesn't look like anybody here has drilled, or had a gunsmith drill, the receiver so the barrel can be cleaned from the correct end without separating it from the receiver. For a variety of reasons, I've never owned a 10/22. Nothing against them; just a not-unlimited budget and there was always something else I wanted more. I know lots of people who do have them. I suppose that's the same as saying I know lots of people. Has anybody here had negative experiences with doing that? It looks like some of the aftermarket receivers have this pre-drilled and some don't. Brownell's sells a jig for $50, which is probably about what your local gunsmith would want to do the job for you. Just curious.

http://www.rimfirecentral.com/forums/showthread.php?t=473981

There's a big difference between cleaning the bore and cleaning/scrubbing the chamber, the original topic of this thread.

12,406 posts

·

Joined 2004

Seems to me that there's been a very "kindly" RFC member who out-sources his 10/22 back receiver face drilling jig FREE to all those who ask. That jig has been through all these great United States and even a couple of close planets................I think.

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

- posts

- 6.9M

- members

- 216K

- Since

- 2002

A family friendly forum community dedicated to rimfire firearm owners and enthusiasts. Come join the discussion of all manner of rimfire pistols, rifles, optics, ammo, gunsmithing, customization, reviews, hunting, accessories, classifieds, and more!

Top Contributors this Month

View All

Al the Infidel

221 Replies

Jayare870

216 Replies

tenbanshee

213 Replies