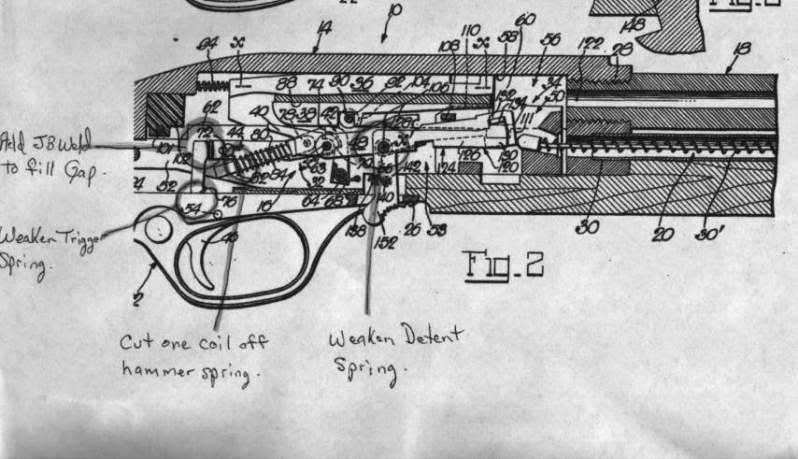

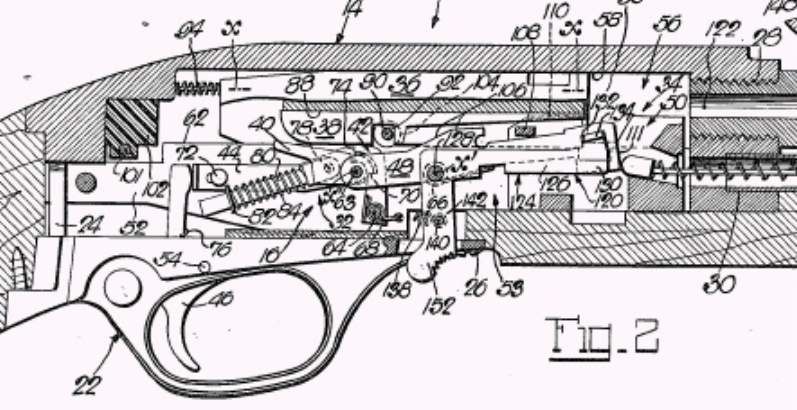

Model 60 trigger pull improvement

OK, you guys got me inspired to do this. I now, so far, have a trigger pull of about 40 oz. which is a helluva lot better than where it was. Here's what I did up to this point & I hope my terminology is close.

1. I did NOT mess with the sear/hammer geometry except grease it.

2. Trigger return [torsion] spring: replaced it with a Floppy Disc Shutter Spring.

3. Hammer [compression] spring No.28 : replaced it with a 3/8 dia x .041w. x 1.25 compression spring. It was about half the spring force however I added 2 little nylon flange bushings in each end to center it up and a steel washer to seat on the guide shoulder. Local hardware store stuff.

4. Disconnector (Trigger linkage) [torsion] spring No.15: I tried to replace that with a FDSS but it would not stay situated so I just modified the existing spring by over stressing [lil more closed] it as another Forum member suggested.

5. Sear [torsion] spring No.43 : I gave that a new anchor point by drilling a new hole in the side plate just below its previous anchor point [the Ejector/Lifter spring stud]. I also bowed that anchor leg to reduce the forces even more. This worked out great and its much easier to dis-assemble too.

The new drilled hole has a c'sink on the outside to help anchor that spring leg too. [Similar the the way the Trigger linkage [torsion] spring is anchored in the side plate.

6. Test fired 10 rounds with no issues. This is sweet. More to come.

http://hometown.aol.com/marklener/page3.html

![Image]()